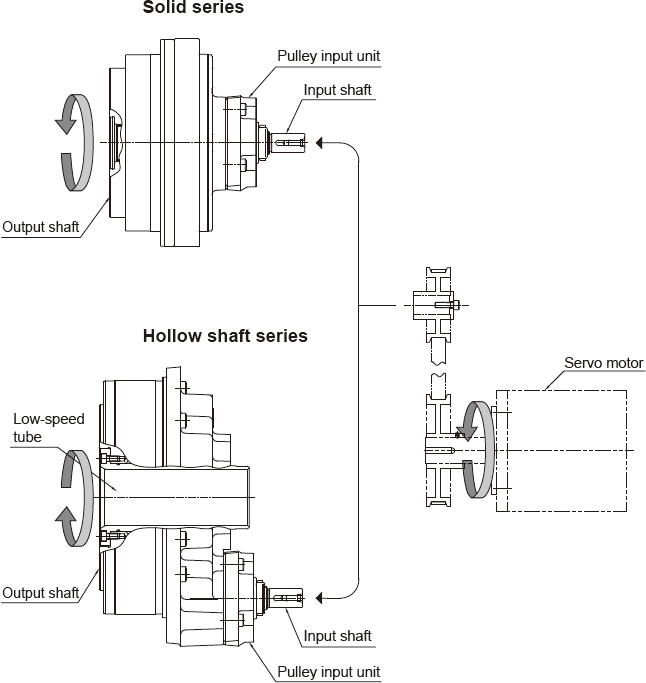

RD2 Series Gearbox :: Mechanism

Installation of the servo motor (for straight and right angle input units)

Step 1

Wipe the outside of the servo motor shaft and the clamping surface inside the coupling with a clean cloth. (Make sure that the clamping bolt of the coupling is not tightened.) When using a bushing, wipe the inside and outside of the bushing using a clean cloth.

Note:

- Make sure that there is no damage inside of the coupling, bushing, and the motor shaft which before perfoming the assembly.

- Make sure that there is no foreign material or oil on the outside of the servo motor shaft, the clamping surface of the coupling, or the inside and outside of the bushing.

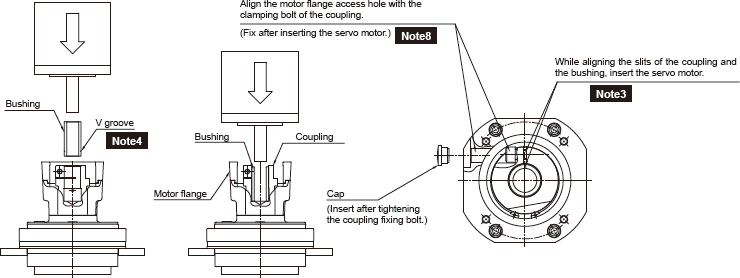

Step 2

When using a bushing, insert the bushing into the coupling, and then align the position of the clamping bolt of the coupling and the motor flange hole.

Note:

- When inserting the bushing, align the slit of the bushing and the slit of the coupling. If the slits of the bushing and coupling are not aligned, proper tightening force cannot be achieved.

- When using the bushing with a V groove on the circumference, turn the V groove toward the back (reduction gear side). If the direction is not correct, proper tightening force cannot be achieved.

Step 3

Wipe off the oil on the installation face of the motor flange and servo motor, and apply the liquid sealing agent on the face.

Note:

- If the servo motor is forcibly inserted into the reduction gear, the servo motor and reduction gear may be damaged.

Configuration Diagram