Engineering

EP's Cycloidal Gear technology is the far superior choice when compared to traditional planetary and cam indexing devices.

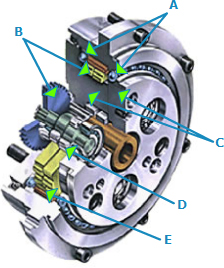

The EP Reducer consists of a patented two-stage cycloidal design that provides large torque, high-ratio and significant shock-load capabilities with extreme precision and excellent quality. The RV gear utilizes rolling contact elements to reduce wear, extend life and lower backlash with the unique pin and gear structure of the cycloidal design providing higher shock resistance than traditional reducers and further reducing backlash. The reducer also incorporates a set of large, internal angular support bearings that provide large moment capacities and negate the need for external support devices.

Content for Members Only

Product selection and drawing data downloads are available.

Planetary Vs Cycloidal

View White Paper

Understanding NMC

View White Paper

Main features include:

- Near Zero Backlash (less than 1 arc-min.)

- High Repeatability (typically 20-30 arc-sec.)

- Large E-Stop Capacity of 5X rated torque

- High Ratio availability - up to 300:1 for hollow shaft gearboxes

- High Torsional Rigidity for very stiff performance

- Hollow Shaft options - up to 5" diameter thru hole

EP's Patented 2-stage Cycloidal Gearbox

- Integrated Angular Ball Bearings

- Allow for support of external loads

- Increase Rigidity and allowable moment

- 2 Stage Reduction Mechanism

- Reduces vibration: Slower rotational speed of the RV gears

- Reduces inertia: Reduced size of input coupling (input gear)

- Dual-Sided Crankshaft Support

- High torsional stiffness, lower vibration & high schock load capability

- Rolling Contact Elements

- Excellent Starting Efficiency

- Low wear and longer life

- Continuous Gear Teeth Contact

- Very low backlash (less than 1 arc-min)

- Higher shock load capability (5x rated torque)

RV Gear Mechanism

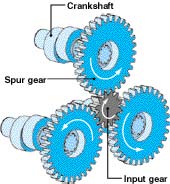

First Stage

The servomotor rotation is transmitted through the input gear to the spur gears, with the speed reduced accordingly. Crankshafts, which are directly connected to the spur gears, rotate at the same speed.

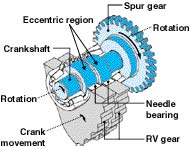

Second Stage

Two RV gears are mounted to the eccentric region of the crankshaft (2 RV gears are used to equally balance forces and to provide continuous teeth contact). As the crankshafts rotate, the two RV gears also revolve. One complete crankshaft rotation causes the RV gears to revolve one pitch of a pin, with all of the RV teeth in constant contact with all of the pins. The pins are arrayed at a constant pitch in the grooves of the gearbox and the number of pins is one larger than the number of teeth. This rotation is then transmitted to the output of the gearbox via the crankshafts at a speed reduced in proportion to the number of pins. The total reduction ratio is equal to the first reduction ratio multiplied by the second reduction ratio.

For any questions, information, or help, email engineering directly: [email protected]